The Concept of 3Rs

Implementing the 3R principles and moving towards

low-carbon, sustainable packaging.

The Concept of 3Rs

Implementing the 3R principles and moving towards low-carbon, sustainable packaging.

Integrating the 3R principles

Our company applies the ‘Recycle,’ ‘Reduce,’ and ‘Reuse’ 3R principles of the circular economy throughout the entire process, including product design and development, material selection, production, and sales, offering a one-stop vertical integration service.

3R Principles

Recycle、Reduce、Reuse

3R Principles

Recycle

Reduce

Reuse

Recycled Plastics

According to data published by the Ellen MacArthur Foundation in 2016, 40% of plastic products produced globally each year are landfilled, 32% enter natural systems, and 14% are incinerated; only 14% are recycled. After accounting for losses and downcycling, only 2% of plastics can be effectively reused through post–consumer recycling (PCR). Post–consumer recycling (PCR) refers to plastics that, after being used and discarded by consumers, are recycled and remanufactured into products of the same type, rather than being turned into lower–grade items. For example, recycled PET bottles are reprocessed into food–grade plastic containers instead of being made into textile fibers for clothing. This model is referred to as closed–loop recycling.

Therefore, we began exploring ways to implement a circular economy within the food packaging sector, enabling plastics to be continuously recycled. This approach helps reduce the environmental impact of plastic waste and the extraction of petrochemical raw materials. Following the “cradle to cradle” regenerative design principles, we established a “clamshell to clamshell” closed–loop recycling system.

Sustainable product sales

Priorities

- Acquisition of product certificate ensures proven use of recycl ed materials

(rPET), degradability, and compostability (PLA)

Achievements in 2023

- Our rPET products (recycled material ratio of 10%, 25%, 50%, and 100%) have passed the SCS Certified Recycled Content certification.

- PLA products have passed the biodegradable and industrially compostable certifications.

Priorities

- Acquisition of product certificate ensures proven use of recycl ed materials

(rPET), degradability, and compostability (PLA)

Achievements in 2023

- Our rPET products (recycled material ratio of 10%, 25%, 50%, and 100%) have passed the SCS Certified Recycled Content certification.

- PLA products have passed the biodegradable and industrially compostable certifications. (See 1.4 Product Certifications)

Raw material selection

Priorities

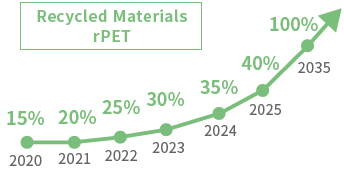

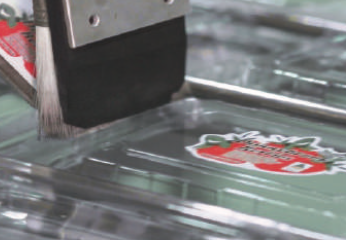

- Pursuit of a gradual increase of the rPET rate to 100% in 2035

Achievements in 2023

- In 2024, the rPET usage rate was 21.15%, still below the 35% target. The main reason is that the customer market remains in an economic recovery phase, resulting in a crowding–out effect from the increased costs of using recycled materials, which impacts the progress of our environmental initiatives. In 2025, we will continue to strengthen communication with customers and highlight the benefits of rPET products to increase usage.

Priorities

- Pursuit of a gradual increase of the rPET rate to 100% in 2035

Achievements in 2023

- In 2024, the rPET usage rate was 21.15%, still below the 35% target. The main

reason is that the customer market remains in an economic recovery phase,

resulting in a crowding–out effect from the increased costs of using recycled

materials, which impacts the progress of our environmental initiatives. In 2025,

we will continue to strengthen communication with customers and highlight the

benefits of rPET products to increase usage.

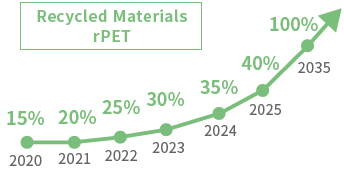

Design process

01 Design sketch creation

Confirm Customer Requirements

02 Proposal Presentation

3D Modeling per Client Requirements

02 Proposal Presentation

3D Modeling per Client Requirements

03Confirmation of Details

Final Confirmation of Product Details and Functional Requirements

04Prototype Production

KYF Mold Factory Prototype Production

04 Prototype Production

KYF Mold Factory Prototype Production

Design and development

Priorities

- In addition to meeting customer requirements while balancing aesthetics and functionality, product design integrates circular economy principles, including the use of low– carbon materials and recycled input materials, as well as raw material reduction. The design also considers the recyclability of products post–use—such as employing mono–materials or transparent coloring—to facilitate effective processing and reuse within the recycling system.

Achievements in 2024

- Since 2018, the Company has been scientifically researching ways to reduce the thickness of existing products without compromising quality or functionality, thereby lowering the consumption of virgin plastic resin. In 2024, one new thin–walled product was introduced. Over the past three years, the cumulative weight reduction of thin–walled products totaled 521 metric tons, resulting in a carbon emission reduction of 1,593 tCO2e.

Priorities

- In addition to meeting customer requirements while balancing aesthetics and functionality, product design integrates circular economy principles, including the use of low– carbon materials and recycled input materials, as well as raw material reduction. The design also considers the recyclability of products post–use—such as employing mono–materials or transparent coloring—to facilitate effective processing and reuse within the recycling system.

Achievements in 2024

- Since 2018, the Company has been scientifically researching ways to reduce the thickness of existing products without compromising quality or functionality, thereby lowering the consumption of virgin plastic resin. In 2024, one new thin–walled product was introduced. Over the past three years, the cumulative weight reduction of thin–walled products totaled 521 metric tons, resulting in a carbon emission reduction of 1,593 tCO2e.

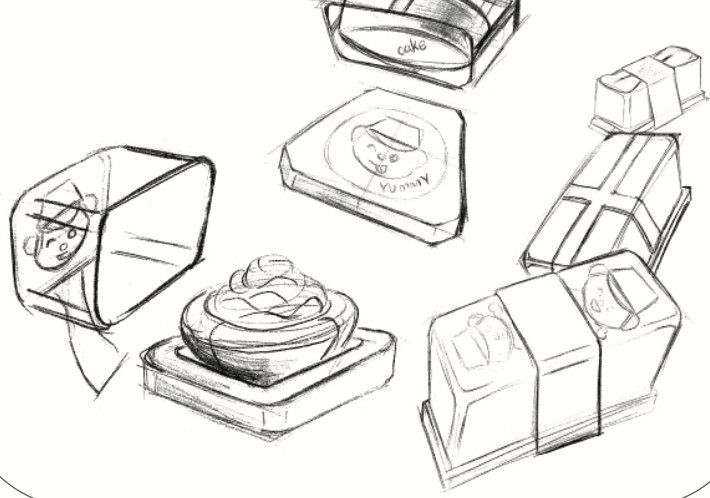

Production process

01Mold Development

CNC Mold Design

02Sheet Extrusion

Produce Semi–finished Products

02Sheet extrusion

Produce Semi–finished Products

03Thermoforming

Production of Finished Products

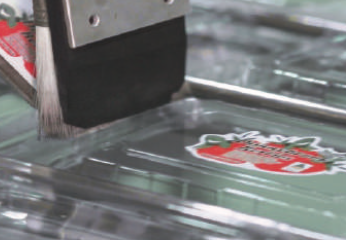

04Added Value

Labeling, Printing, Additional processing

04 Added value

Labeling, Printing, Additional processing

Manufacturing

Priorities

- The extruder and the thermoforming machine—are equipped with regrind recovery systems. Trimmed internal production scrap is shredded, sorted by material and color, and stored as regrind material, which is then reused in the production process. This internal recycling practice supports the reduction of waste diverted from disposal and promotes resource efficiency.

Achievements in 2024

- In 2024, reused regrind materials totaled 46,923 metric tons, accounting for 47.58% of total input materials used.

Priorities

The extruder and the thermoforming machine—are equipped with regrind recovery systems. Trimmed internal production scrap is shredded, sorted by material and color, and stored as regrind material, which is then reused in the production process. This internal recycling practice supports the reduction of waste diverted from disposal and promotes resource efficiency.

Achievements in 2024

粉

In 2024, reused regrind materials totaled 46,923 metric tons, accounting for 47.58% of total input materials used.。