Closed – loop recycling

It is our firm conviction that recycled plastics are the best way to mitigate the environmental impact of plastic waste and reduce the extraction of fossil raw materials.

One of the most prominent examples of the application of the “cradle–to–cradle” philosophy is PET bottle–to–bottle recycling. We have also adopted this philosophy for the development of our “clamshell– to– clamshell” closed–loop recycling.

Closed – loop recycling

It is our firm conviction that recycled plastics are the best way to mitigate the environmental impact of plastic waste and reduce the extraction of fossil raw materials.

One of the most prominent examples of the application of the “cradle–to–cradle” philosophy is PET bottle–to–bottle recycling. We have also adopted this philosophy for the development of our “clamshell– to– clamshell” closed–loop recycling.

According to a United Nations report, one-third of global food is wasted, resulting in carbon emissions as high as 440,000 tons. Food waste leads to significant economic losses and incurs enormous environmental costs, further exacerbating global warming and the climate change crisis.

We found…

According to statistics from Taipei Agricultural Products Marketing Corporation in May 2023, food waste increased by 800%, from 1.2 tons of discarded fruits and vegetables per month before bare selling to 10.8 tons per month after bare selling. In an effort to reduce packaging materials, this resulted in even more food waste.

Source: Taipei Agricultural Products Marketing Corporation

Reducing plastic waste vs. reducing fruit and vegetable waste: Finding a balance between the two offers a better solution

The packaging box serves to protect the products and prevent collisions, reducing the likelihood of damage or spoilage when consumers handle and select fruits in the bare-selling section of the store. Consumers are encouraged to return the packaging box for recycling after checkout, allowing it to enter a circular reuse system. This not only protects the food and reduces spoilage costs, but also prevents additional plastic extraction, reduces environmental burdens, and helps achieve a more proactive plastic reduction goal.

Source: SimaPro

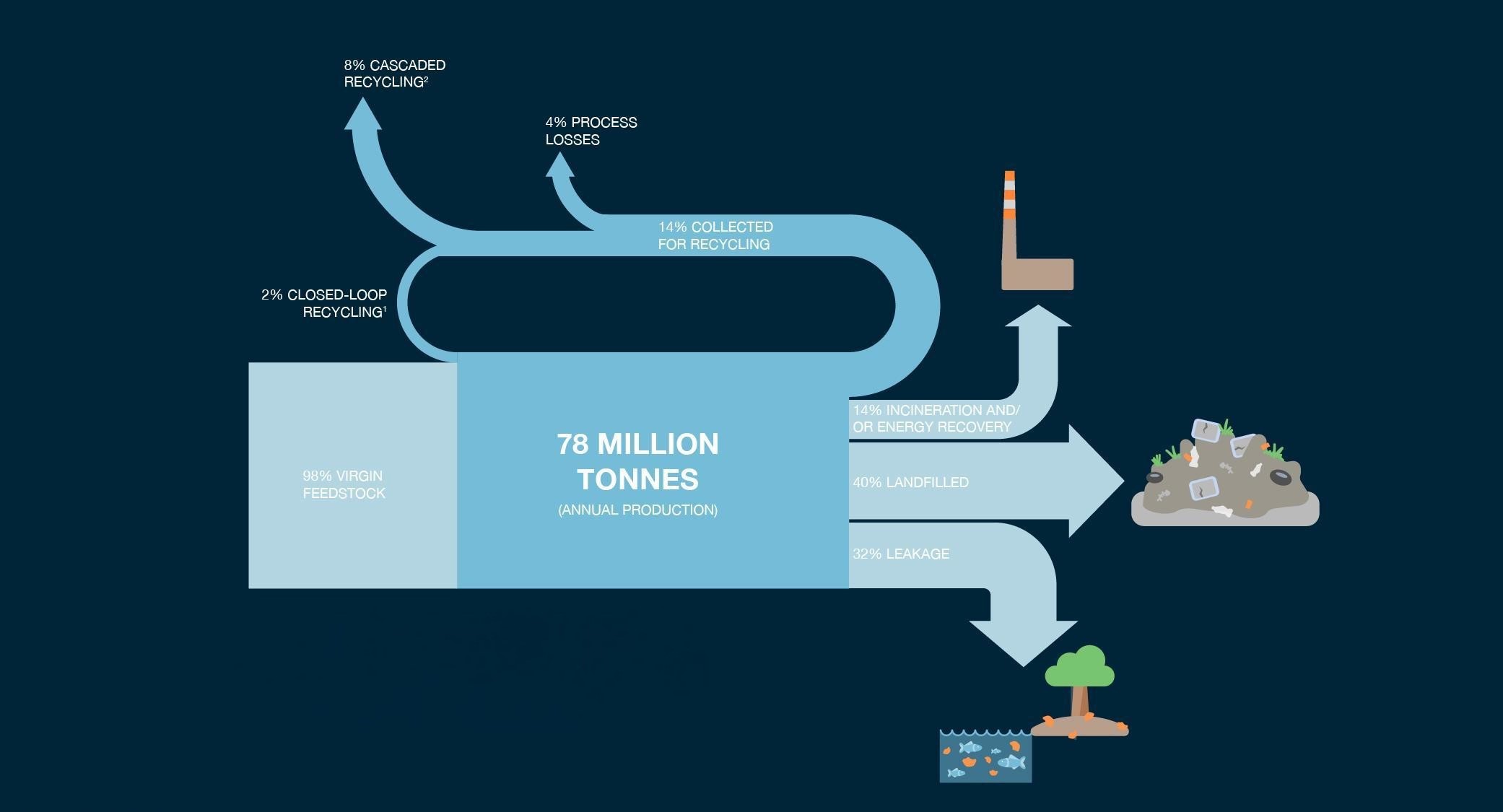

According to data published by the Ellen MacArthur Foundation in 2016, 40% of plastic products produced globally each year are landfilled, 32% enter natural systems, and 14% are incinerated; only 14% are recycled. After accounting for losses and downcycling, only 2% of plastics can be effectively reused through post–consumer recycling (PCR). Post–consumer recycling (PCR) refers to plastics that, after being used and discarded by consumers, are recycled and remanufactured into products of the same type, rather than being turned into lower–grade items. For example, recycled PET bottles are reprocessed into food–grade plastic containers instead of being made into textile fibers for clothing. This model is referred to as closed–loop recycling.

Therefore, we began exploring ways to implement a circular economy within the food packaging sector, enabling plastics to be continuously recycled. This approach helps reduce the environmental impact of plastic waste and the extraction of petrochemical raw materials. Following the “cradle to cradle” regenerative design principles, we established a “clamshell to clamshell” closed–loop recycling system.

In August 2024, KYF, in partnership with Carrefour Taiwan and BoReTech, took the lead in establishing Taiwan’s first closed-loop recycling site for PET clamshell packaging at Carrefour Kaohsiung Love River Store, and will continue to actively expand recycling station sites in the future. In addition, KYF participated in the Sustainable Innovation Hackathon competition as a corporate challenger, jointly exploring ways to promote the circular economy and application of related resources, and deepening industry–academic exchanges and cooperation.

Recycling station business model: Chain supermarkets and hypermarkets utilize No. 1 PET packaging boxes that protect products and reduce damage. These boxes can be recycled and remanufactured into new packaging, which is then supplied back to the retailers. This “clamshell to clamshell” circular economy ensures that packaging no longer adds extra plastic burden to the planet, reduces reliance on virgin plastic, advances toward net–zero carbon emissions, and maximizes resource value.